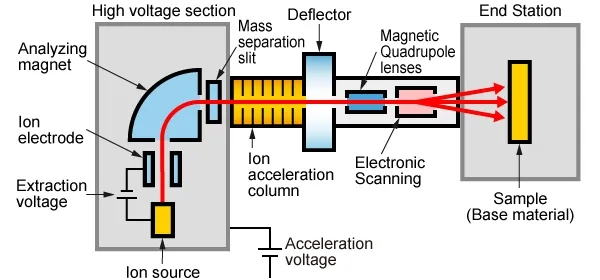

Ion implantation is a process used in the semiconductor industry to introduce dopants or impurities into a material, typically a silicon wafer, in order to alter its electrical properties. This process involves the acceleration of ions, such as boron or phosphorus, to high energies and then directing them towards the surface of the material to be implanted.

During the process of ion implantation, the high-energy ions penetrate the surface of the material and become embedded in the crystal lattice of the material. This alters the number of electrons in the lattice and can create either a p-type or n-type semiconductor. The doping process helps to create regions of differing electrical conductivity, which are necessary for creating the structures needed in microelectronic devices such as transistors and diodes.

Ion implantation is a critical step in the manufacturing of semiconductors and is used to create precise doping profiles for the production of integrated circuits. The process is also used in other industries, such as the aerospace industry, to modify the surface properties of materials.

Relying on strong machining capabilities and strict control of product quality, Belong metals has rich experience in producing tungsten and molybdenum ion implanter parts. These has been exporting to many countries and regions all year round such as Europe, America, Japan and South Korea. Our products are widely used as Chambers, filaments, panels, brackets, cathodes and other parts in various types of ion implantation.

Frank Guo

Frank Guo

+86 13026443801

+86 13026443801

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

sales@belongmetal.com

sales@belongmetal.com

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China