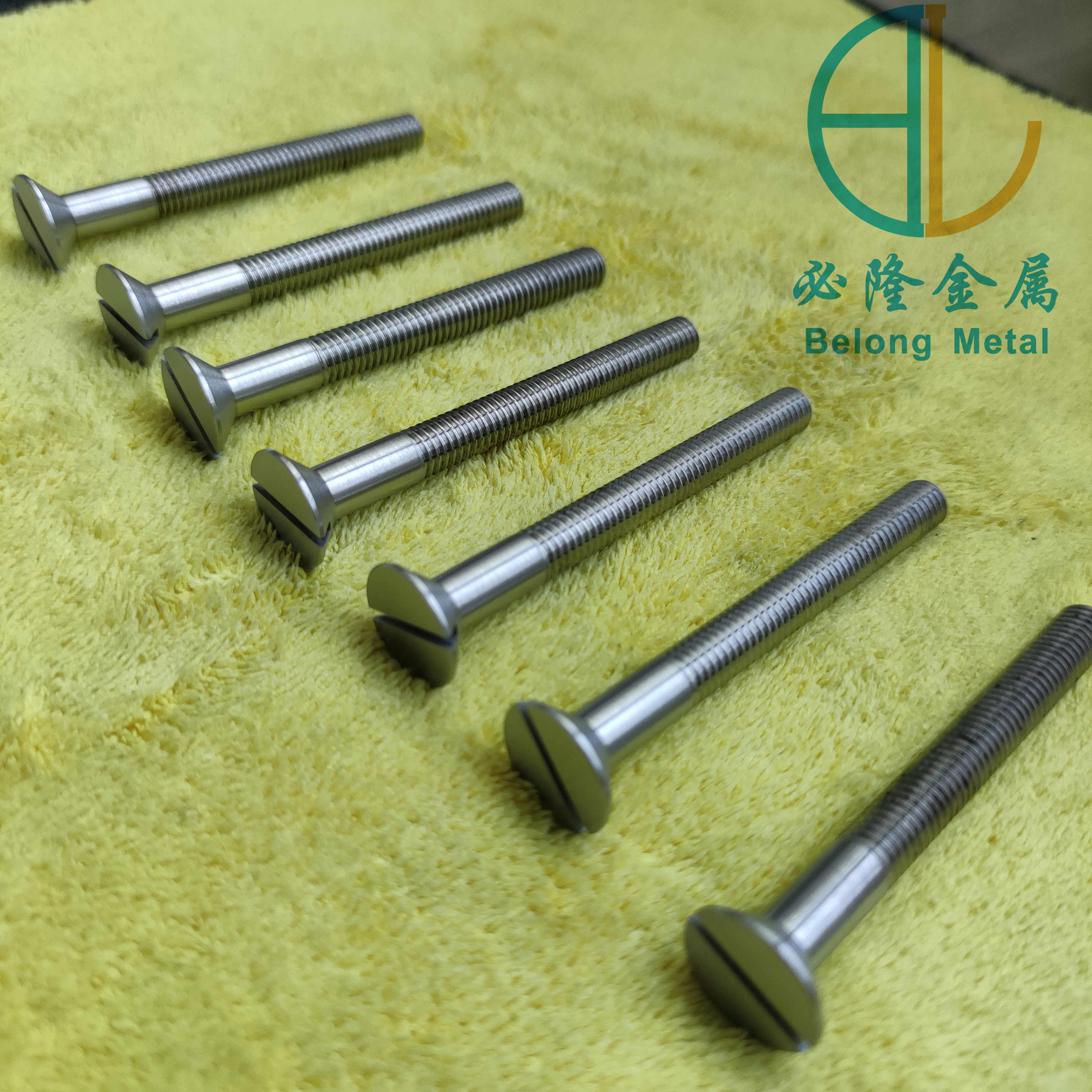

Tungsten screw processing, application and characteristics

1. Fasteners are important components for connecting and fixing various mechanical parts. With the development of science and technology, the performance requirements of fasteners are getting higher and higher. Tungsten screw, with its unique advantages, has gradually become the new darling of the fastener market.

2. Basic concept of tungsten screw

Tungsten screw is a fastener made of tungsten alloy, which has the characteristics of high density, high strength, high hardness and good thermal conductivity. Tungsten alloy is an alloy composed of tungsten, nickel, iron and other elements, with excellent comprehensive properties.

3. Material characteristics

(1) High density: The density of tungsten screws can reach 16.5-18.5g /cm3, which is much higher than ordinary steel screws.

(2) High strength: the tensile strength of tungsten alloy can reach 1100-1500 MPa, which is 2-3 times that of ordinary steel.

(3) High hardness: The hardness of tungsten alloy can reach HRC45-50, with excellent wear resistance.

(4) Good thermal conductivity: tungsten alloy has a high thermal conductivity, which is conducive to the rapid transfer of heat.

4. Manufacturing process

Tungsten screw manufacturing process mainly includes:

(1) Powder metallurgy: through powder pressing, sintering and other processes to prepare tungsten alloy blanks.

(2) Forging: forging tungsten alloy blanks to improve its density and strength.

(3) Machining: the tungsten alloy after forging is turned, milling and other processing to form the required screw shape.

(4) Heat treatment: Through quenching, tempering and other heat treatment processes, improve the hardness and wear resistance of tungsten screws.

5. Application field

(1) Aerospace: Tungsten screws can be used for the connection of key components such as aircraft engines and rocket engines.

(2) Military: Tungsten screws can be used for fastening military equipment such as tanks and missiles.

(3) Electronics: Tungsten screws can be used for heat dissipation components of high-performance electronic devices.

(4) Medical: Tungsten screws can be used for artificial joints, dental implants and other medical devices.

6. Future development trend

With the continuous progress of science and technology, tungsten screws will have greater breakthroughs in the field of performance and application. In the future, tungsten screws are expected to make progress in the following aspects:

(1) Material innovation: Research and development of new tungsten alloy to improve the performance of tungsten screws.

(2) Manufacturing process optimization: the use of advanced manufacturing technology, reduce production costs, improve production efficiency.

(3) Application field expansion: Develop more high-performance fasteners to meet the needs of different industries.

7. Conclusion

As a kind of high performance fastener, tungsten screw has a wide application prospect in many fields. With the development of science and technology, the performance of tungsten screws will continue to improve, the application field will continue to expand, and make greater contributions to the progress of human society.

Through this introduction of Baoji Belong Metal, I believe you have a more in-depth understanding of tungsten screws. With its excellent performance, tungsten screws are gradually becoming the new darling of the fastener market, providing solid support for a variety of high-tech products.

Frank Guo

Frank Guo

+86 13026443801

+86 13026443801

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

+86 0917-3228322

sales@belongmetal.com

sales@belongmetal.com

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China

Guojiacun Industrial zone, Maying Town, Weibin Zone, Baoji, Shaanxi 721000, P.R.China